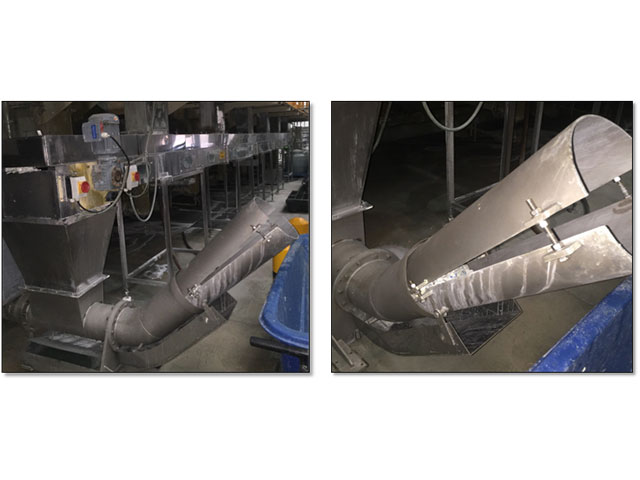

Wasted label compressor

The machine is professional compressed surface water with the material,through the spiral, hydraulic and other means to compress the water with thematerial,

Product introduction:

The machine is professional compressed surface water with the material,through the spiral, hydraulic and other means to compress the water with thematerial, and then discharged from the machine, the bottom of the dischargedevice filled with holes to drain Role, for dealing with water trademark paper,paper and so on. Products for professional brewery models of 20,000 bottlesto 50,000 bottles of bottles of waste trademark paper processing. This productis made of stainless steel to prevent corrosion. The compressed paper withcompressed water is compressed into a cluster, and the compressed material canbe transported outside by the automatic discharging device, thus ensuring theenvironmental sanitation of the bottle-washing machine production site and thetransportation process and reducing the labor intensity. The compact structureof the device, small footprint, can be moved, is the processing plant beer bottlewashing machine waste paper trademark ideal equipment.

Structure:

★Spiral pressure dryer from the drive motor, the activities of the wheel, screw shaft components, sleeve, the material device and other components.

★Hydraulic pressure dry machine is mainly composed of hydraulic system, movable wheel, balance adjustment assembly, cylinder, outrigger, electric cabinet, oil tank and so on.

Technical parameters (hydraulic pressure type):

★Equipment model: JG-FB-250-Y

★The main material: 304 stainless steel

★Equipment dimensions: (length x width x high) 2200x700x1100mm

★Material inlet docking size: (length x width) 560x400mm(Adjustable)

★Material export height: 600-1000mm (adjustable)

★Material export size:250mm

★Discharge port can be rotated angle: 30°~ 45~ 60°

★Hydraulic station fuel tank capacity: hydraulic oil 46 # 50l

★Hydraulic pump motor power: 1.5Kw 380v

★Squeeze the maximum stroke piston: 620mm

★Extruded paper containing water: less than 30%

Technical parameters (screw type):

★Equipment model: JG-FB-250-L

★The main material: 304 stainless steel

★Equipment dimensions: (length x width x high) about 1850x600x900mm

★Material inlet butt size: (length x width) 700x400mm(Adjustable)

★Material export height: 600-1000mm (adjustable)

★Screw outlet diameter: 250mm

★Discharge port rotation angle: 30°~ 45°~ 60°

★Motor power: 1.5KW-2.2KW

★Extruded paper containing water: less than 30%

Equipment characteristic:

★Use of spiral, hydraulic squeeze;

★Automatic discharge, easy to push out the paper machine outside the machine;

★Equipment for the production of stainless steel to prevent corrosion;

★Manual, automatic switching, easy to operate, without human intervention;

★Equipment covers an area of small, easy to shift;

★Reduce labor intensity, improve work efficiency;

★Reduce pollution, improve the working environment.

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

High pressure backwash filter

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.

Wasted label compressor

The machine is professional compressed surface water with the material,through the spiral, hydraulic and other means to compress the water with thematerial,

Learn MoreBottle crush, lift & store system

Bottle crush, lift & store system can effectively reduce the operator from the workshop and the residue of the temporary storage area of the distance and time, reduce the intensity of work and improve efficiency, and one can achieve the size of the glass slag recovery requirements, remove the broken bottles of artificial links.

Learn MoreBottle Cleaner & Blower

The machine uses advanced air knife technology, stable performance, low temperature operation, high visibility, good drying effect, suitable for high speed production line.

Learn More